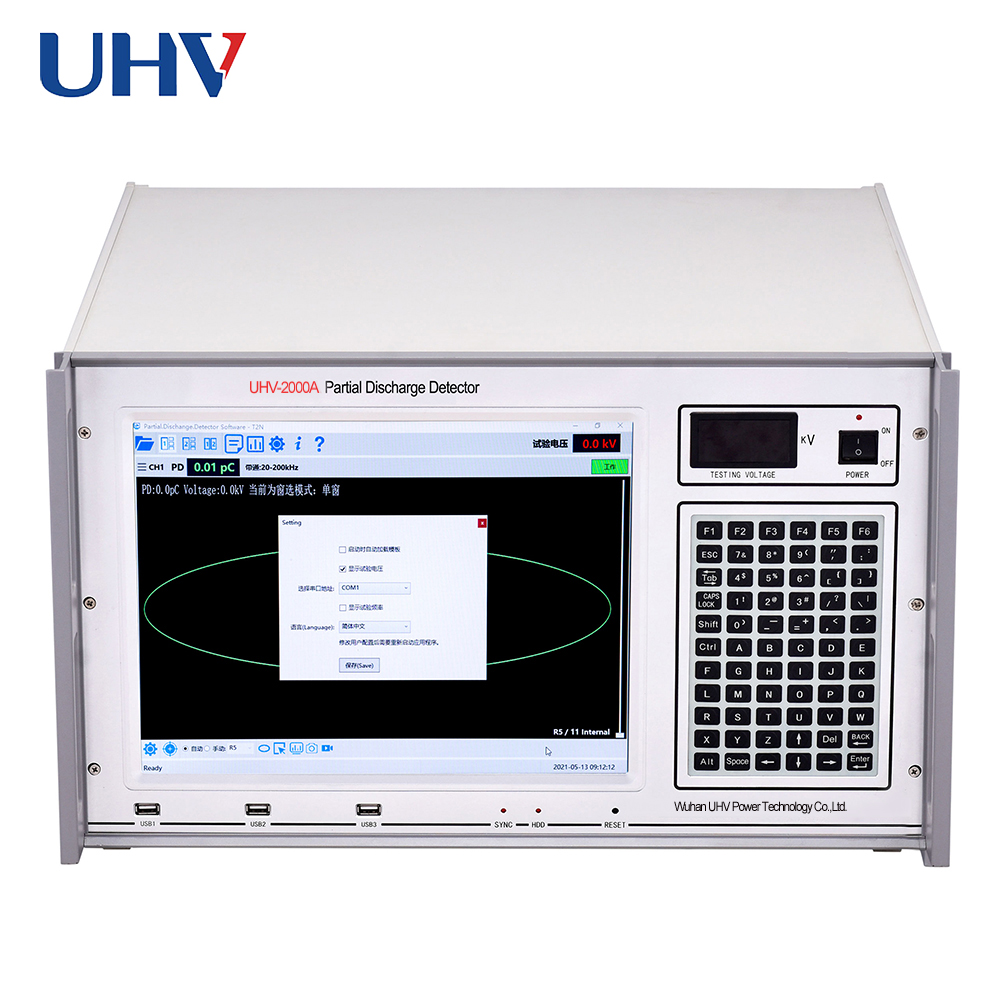

Wuhan UHV specializes in the production of partial discharge testers, which can help many power workers to carry out all kinds of power tests more conveniently.

Partial discharge of transformers (reactors) can be detected by pulsed current and ultrasonic.

1. Pulsed current method.

There is a distributed capacitance between the transformer (reactor) winding and the core, and the discharge signal is a high-frequency signal ranging from a few hundred kilohertz to a few megahertz. It can be capacitively transmitted from the windings to the core, which generates a high-frequency current in the core clamp. If a high-frequency current transformer (HFCT) is mounted on the core or core clamp grounding wire, a partial discharge pulse signal can be detected.

2. Ultrasonic.

Once a partial discharge occurs in a transformer (reactor), an ultrasonic signal will be generated and propagated to the surrounding spherical form. By placing an ultrasonic sensor on the outer wall of a transformer (reactor) tank, the ultrasonic signal generated by the discharge can be detected.

These two assays can be used together or separately. If these two methods are used at the same time, it is possible to detect various discharge signals easily and flexibly in the transformer (reactor), and the fault location of partial discharge can be judged based on the time difference between the two signals.