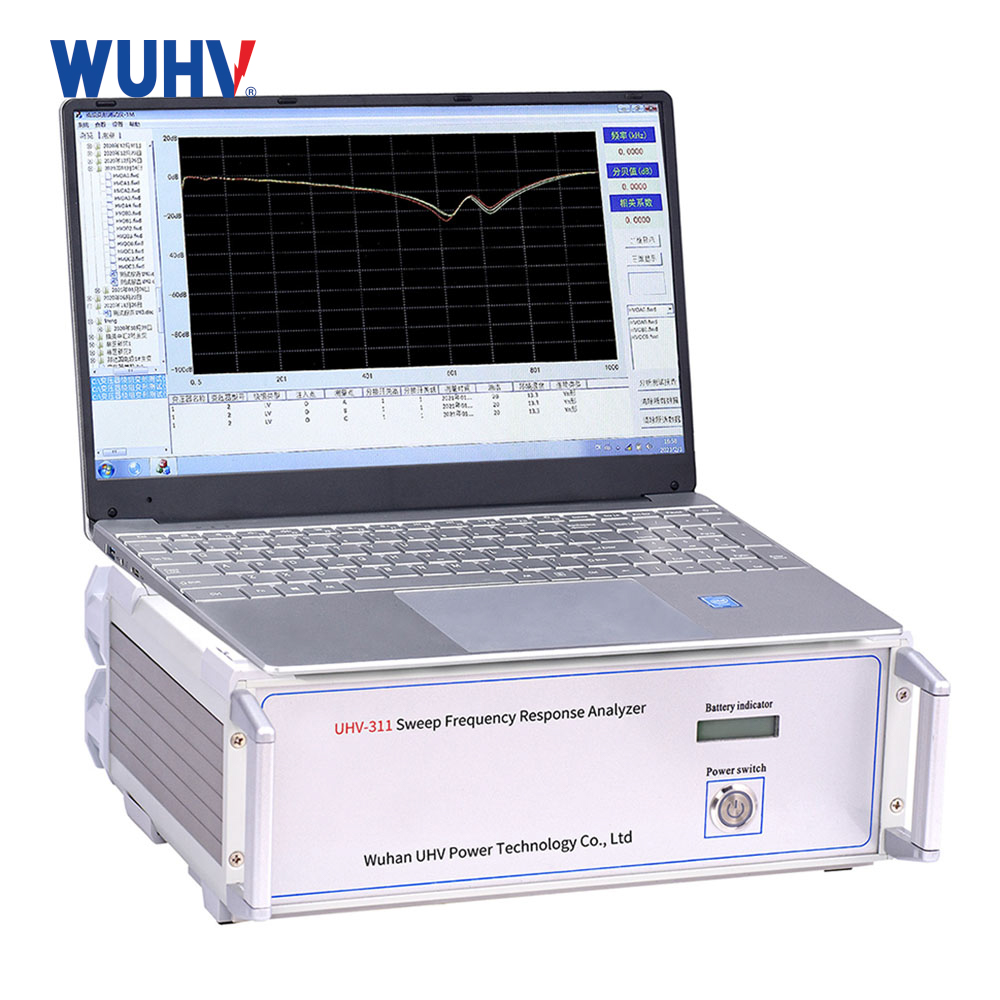

Технические характеристики

Тестовый ток | 10А、20A、40A、100A |

measuring range

| 10μΩ~100mΩ(100A) |

100μΩ~500mΩ(40A) | |

200μΩ~1Ω(20A) | |

500μΩ~2Ω(10A) | |

Точность | 0.2% |

resolving power | 0,1 мОм |

working temperature | 0~40℃ |

ambient humidity | ≤ 90% RH, no condensation |

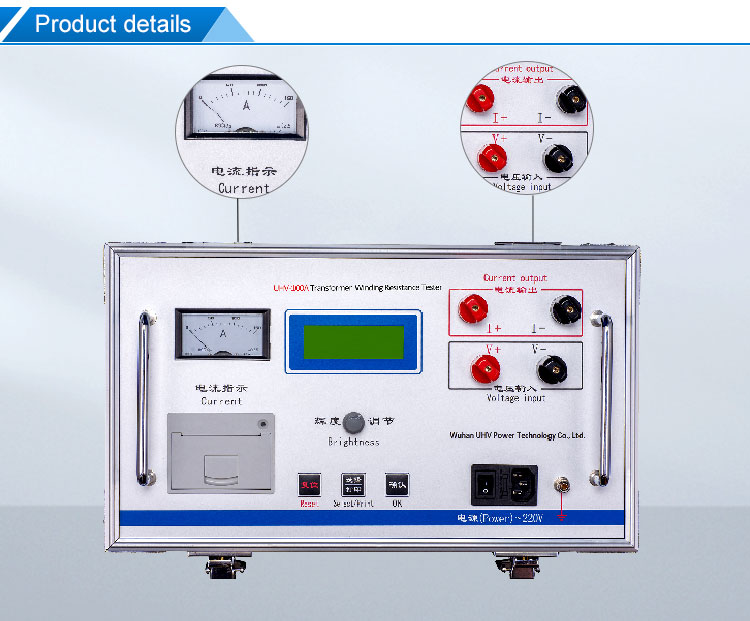

Рабочий источник питания | 220 В переменного тока ± 10%,50 Гц±1 Гц |

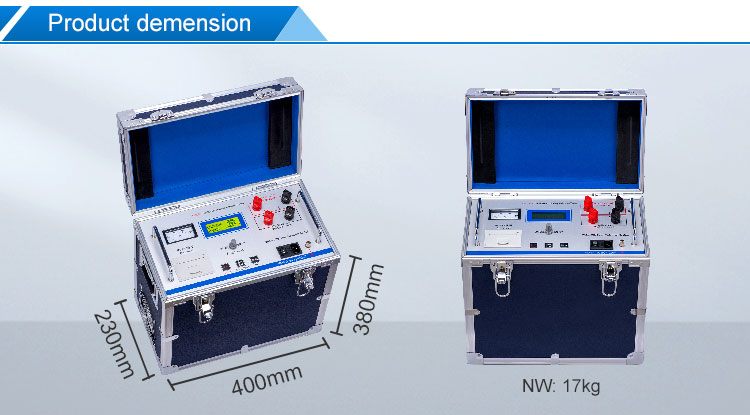

масса | 17 кг |

External dimensions | 400×230×380mm3 |

Псевдоним:DC Winding Resistance Tester,Resistance Meter,Three-circuit Transformer DC Resistance Tester

Security measures:

1. Before using this instrument, it is necessary to carefully read the instruction manual.

2. The user of the instrument should have general electrical knowledge.

3. Avoid using the instrument in places where it is exposed to rain, corrosive gases, excessive dust, high temperatures, direct sunlight, etc.

4. The instrument should avoid long-term bumps and severe vibrations.

5. Maintenance and debugging of instruments should be carried out by professionals.

After the test is completed, be sure to wait for the discharge alarm sound to stop before turning off the power and removing the test line.

7. When measuring an unloaded voltage regulating transformer, be sure to wait for the discharge indicator alarm sound to stop before switching gears.

During the testing process, it is prohibited to move the test clamp and power supply line.

Precautions:

1. Before testing the no-load tap changer of the transformer, it must be reset. After the discharge is completed, the alarm sound should stop for more than 10 seconds before switching the tap changer.

2. Before disconnecting, be sure to wait for the discharge to end and the alarm sound to stop. It is best to wait for more than 10 seconds before disconnecting to ensure that the charge is completely released.

3. When selecting the current, refer to the range in the technical specifications column and do not use it beyond or below the range. When the current exceeds the preset value, the instrument remains in the "charging" state. When the range is insufficient, it displays' current too low '. When these two states occur, confirm the range and select the appropriate current for testing.

4. Pay attention to the range when using the magnetic assist method. Because two high-voltage coils are connected in parallel and one is connected in series, 1.5 times the resistance of the high-voltage coil is added to the entire testing circuit, and the range selection needs to be taken into account. If the output current cannot reach the set value or is unstable when using beyond the range.

5. When the short contacts of the three wires of the magnetic assist method are removed after discharge, there may be residual current, which may cause ignition and discharge during removal. This is a normal phenomenon.

6. When connecting the test clamp to the lead out terminal of the transformer winding, it is important to note that the lead out terminal is exposed to air for a long time, and the surface of the lead out terminal is covered with an oxide film, which may cause unstable or inaccurate measurement results. Therefore, when wiring, attention should be paid to cleaning the oxide film, or after connecting the test clamp to the lead out terminal, twist the test clamp vigorously a few times to cut through the oxide film to ensure a good connection.